Inqubo Yokukhiqiza Ye-Graphite Electrode

I-electrode ye-graphite iwuhlobo lwe-graphite conductive material ekwazi ukumelana nokushisa okuphezulu ekhiqizwa kusetshenziswa i-petroleum coke, i-coke yenaliti njenge-aggregate, i-asphalt yamalahle njenge-binder, ngemva kochungechunge lwezinqubo ezifana nokuxuba, ukubumba, ukugazinga, ukucwiliswa, i-graphitization kanye nokucutshungulwa komshini.

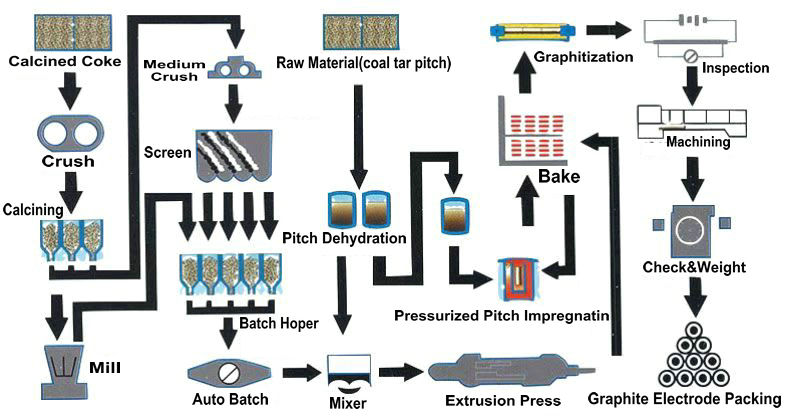

Izinqubo zokukhiqiza eziyinhloko ze-graphite electrode zimi kanje:

(1) Ukubalwa.I-petroleum coke noma i-asphalt coke idinga ukwenziwa, futhi izinga lokushisa lokubala kufanele lifinyelele ku-1300 ℃, ngakho-ke ukuze kususwe ngokugcwele okuqukethwe okuguquguqukayo okuqukethwe ku-carbon eluhlaza, futhi kuthuthukiswe ukuminyana kweqiniso, amandla emishini kanye nokuhamba kukagesi kwe-coke.

(2) ukuchotshozwa, ukuhluzwa, kanye nezithako.Izinto zokusetshenziswa kwekhabhoni ezibaliwe ziyaphulwa futhi zihlolwe zibe yizinhlayiya ezihlanganisiwe zobukhulu obushiwo, ingxenye ye-coke igaywe ibe yimpushana, futhi ingxube eyomile igxiliswe ngokuvumelana nefomula.

(3) Hlanganisa.Esimweni sokushisisa, ingxube eyomile yobuningi yezinhlayiya ezihlukahlukene ixutshwa ne-quantitative binder, ixutshwe futhi ixove ukuze kuhlanganiswe unamathisele wepulasitiki.

(4) ukubumba, ngaphansi kwesenzo sokucindezela kwangaphandle (ukwakheka kwe-extrusion) noma ngaphansi kwesenzo sokudlidliza kwefrikhwensi ephezulu (ukwakheka kokudlidliza) ukucindezela ukunamathisela kusimo esithile kanye nokuminyana okuphezulu kwe-electrode eluhlaza (billet).

(5) Ukubhaka.I-electrode eluhlaza ifakwe esithandweni esikhethekile sokushisa, futhi i-coke powder ye-metallurgical igcwele futhi ihlanganiswe ne-electrode eluhlaza.Emazingeni okushisa aphezulu e-ejenti yokubopha engaba ngu-1250 ℃, i-carbon electrode yokugazinga yenziwa.

(6) Omsulwa.Ukuze kuthuthukiswe ukuminyana namandla emishini yemikhiqizo ye-electrode, i-electrode yokugazinga ilayishwa emishinini yamandla kagesi aphezulu, bese i-asphalt ye-agent ecwilisa uketshezi icindezelwa emgodini womoya we-electrode.Ngemuva kokucwiliswa, ukugazinga kufanele kwenziwe kanye.Ngokwezidingo zokusebenza komkhiqizo, kwesinye isikhathi ukufakelwa kanye nokugazinga kwesibili kufanele kuphindwe izikhathi ezingama-23.

(7) ukwenza i-graphitization.I-carbon electrode ebhakiwe ilayishwa esithandweni se-graphitization, embozwe ngezinto zokufakelwa.Ngokusebenzisa indlela yokushisa yokufaka ugesi okuqondile ukuze kukhiqizwe izinga lokushisa eliphezulu, i-carbon electrode iguqulwa ibe i-graphite electrode ene-graphite crystal structure ekushiseni okuphezulu kuka-2200 ~ 3000℃.

(8) ukwenza imishini.Ngokwezidingo zokusetshenziswa, i-graphite electrode ephenduka indawo engenalutho, indawo yokugcina eyisicaba kanye nezimbobo zesikulufu zokucubungula uxhumano, kanye nejoyinti ukuze kuxhunywe.

(9) I-electrode ye-graphite izopakishwa kahle ngemva kokudlulisa ukuhlolwa futhi ithunyelwe kumsebenzisi.

Isikhathi sokuthumela: Jun-01-2023