RP 600mm 24inch Graphite Electrode Ye-EAF LF Smelting Steel

Ipharamitha Yezobuchwepheshe

| Ipharamitha | Ingxenye | Iyunithi | RP 600mm(24”) Idatha |

| Ububanzi Okuzisholo | I-Electrode | mm(intshi) | 600 |

| I-Max Diameter | mm | 613 | |

| Ububanzi obuncane | mm | 607 | |

| Ubude Begama | mm | 2200/2700 | |

| Ubude obukhulu | mm | 2300/2800 | |

| Ubude obuncane | mm | 2100/2600 | |

| Ukuminyana Kwamanje Okuphezulu | KA/cm2 | 11-13 | |

| Ikhono Lamanje Lokuthwala | A | 30000-36000 | |

| Ukumelana Okuqondile | I-Electrode | μΩm | 7.5-8.5 |

| Ingono | 5.8-6.5 | ||

| Amandla e-Flexural | I-Electrode | Mpa | ≥8.5 |

| Ingono | ≥16.0 | ||

| I-Modulus Encane | I-Electrode | I-Gpa | ≤9.3 |

| Ingono | ≤13.0 | ||

| Ukuminyana kwenqwaba | I-Electrode | g/cm3 | 1.55-1.64 |

| Ingono | ≥1.74 | ||

| I-CTE | I-Electrode | ×10-6/℃ | ≤2.4 |

| Ingono | ≤2.0 | ||

| Okuqukethwe Umlotha | I-Electrode | % | ≤0.3 |

| Ingono | ≤0.3 |

QAPHELA: Noma yiziphi izimfuneko ezithile kubukhulu zinganikezwa.

Indlela Yokulungisa I-Graphite Electrode

Ngaphezu kokukhetha i-electrode ye-graphite efanele ye-RP, ukugcinwa kubalulekile ukuze kuqinisekiswe impilo ende nokusebenza kahle kwe-electrode.Ukuphatha kahle kanye nokugcinwa kwe-electrode kubalulekile ukunciphisa ingozi ye-electrode oxidation, i-sublimation, ukuchithwa, i-spalling, kanye nokuphuka.Lapho i-electrode isetshenziswa, opharetha wesithando somlilo kufanele anake ukuguga nokudabuka kwe-electrode futhi alungise indawo ye-electrode nokokufaka kwamandla ngokufanele.Ukuhlolwa okufanele kwangemuva kokulungiswa, okuhlanganisa ukuhlola okubonakalayo nokuhlolwa kokusebenza kukagesi, kungasiza futhi ukukhomba noma yimuphi umonakalo ongase ube khona noma ukuwohloka kwe-electrode.

Ukunikezwa Kwemiyalo Nokusetshenziselwa Ama-Electrode E-graphite

- Sebenzisa amathuluzi okuphakamisa akhethekile ukuze uphile i-electrode yegraphite gwema ukulinyazwa ngesikhathi sokuthutha.(bona isithombe1)

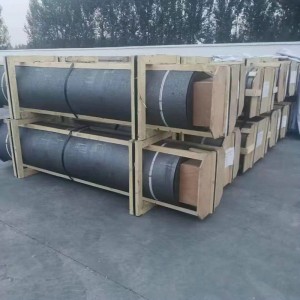

- I-electrode ye-graphite kufanele igcinwe ikude ukuze ingamanziswa noma imanziswe yimvula, iqhwa, igcinwe yomile.(bona pic2)

- Ukuhlola ngokucophelela ngaphambi kokusetshenziswa qinisekisa ukuthi isokhethi nentambo yengono ilungele ukusetshenziswa, okuhlanganisa nokuhlolwa kwephimbo, ipulaki.(bona pic3)

- Hlanza ingono nezisekelo zochungechunge ngomoya ocindezelweyo.(bona pic4)

- Ngaphambi kokusetshenziswa, i-electrode yegraphite kumele yomiswe esithandweni, izinga lokushisa lokumisa kufanele libe ngaphansi kuka-150 ℃, isikhathi esomisiwe kufanele sibe ngaphezu kwamahora angu-30. (bona pic5)

- I-electrode yegraphite kufanele ixhunywe ngokuqinile futhi iqonde ngetorque efanelekile yokuqinisa.(bona pic6)

- Ukuze ugweme ukuphuka kwe-electrode ye-graphite, beka ingxenye enkulu endaweni ephansi kanye nengxenye encane endaweni ephezulu.

Ishadi le-RP Graphite Electrode Yamanje Ethwala Ikhono

| Ububanzi Okuzisholo | Amandla Avamile(RP) Ibanga Le-Graphite Electrode | ||

| mm | Intshi | Ikhono Lamanje Lokuthwala(A) | Ukuminyana Kwamanje(A/cm2) |

| 300 | 12 | 10000-13000 | 14-18 |

| 350 | 14 | 13500-18000 | 14-18 |

| 400 | 16 | 18000-23500 | 14-18 |

| 450 | 18 | 22000-27000 | 13-17 |

| 500 | 20 | 25000-32000 | 13-16 |

| 550 | 22 | 28000-36000 | 12-15 |

| 600 | 24 | 30000-36000 | 11-13 |