Induku Encane Ye-Diameter Graphite Electrodes Yesithando Somlilo Se-Arc Embonini Yensimbi Ne-Foundry

Ipharamitha Yezobuchwepheshe

Ishadi 1:Ipharamitha Yobuchwepheshe Ye-Electrode Encane Ye-Diameter Graphite

| Ububanzi | Ingxenye | Ukumelana | Amandla e-Flexural | I-Modulus Encane | Ukuminyana | I-CTE | Umlotha | |

| Intshi | mm | μΩ·m | I-MPa | I-GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Ishadi 2:Ikhono Lamanje Lokuthwala Le-Electrode Encane Eyi-Diameter Graphite

| Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Izinzuzo

Ukwelashwa kwe-1.Anti-oxidation yokuphila isikhathi eside.

2.Ukuhlanzeka okuphezulu, ukuminyana okuphezulu, ukuzinza kwamakhemikhali okuqinile.

3.Ukunemba okuphezulu kwemishini, ukuqedwa okuhle kwendawo.

4.Amandla aphezulu emishini, ukumelana nogesi okuphansi.

5.Ingavimbeli ukuqhekeka nokuphuma.

6.Ukumelana okuphezulu kwe-oxidation kanye nokushaqeka okushisayo.

Isicelo Esiyinhloko

- Ukuncibilika kwe-calcium carbide

- Ukukhiqizwa kwe-Carborundum

- Ukucwenga i-Corundum

- Ukuncibilika kwezinsimbi ezingavamile

- I-Ferrosilicon plant refractory

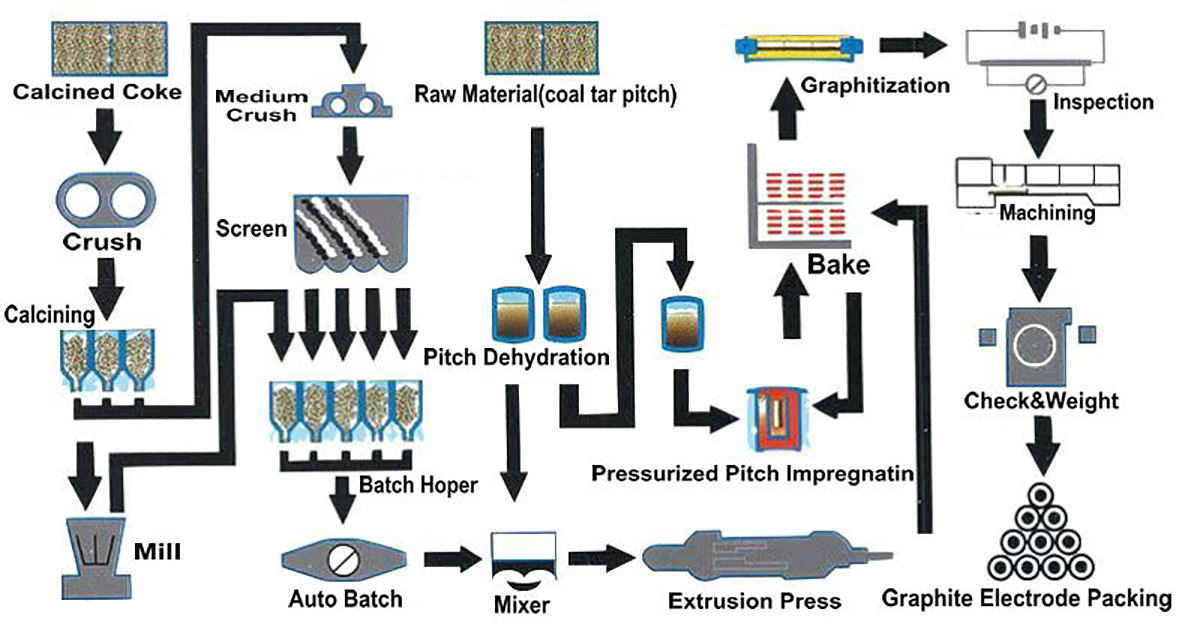

I-RP Graphite Electrode Production Process

I-Surface Quality Ruler

1.Ukukhubazeka noma izimbobo akufanele zibe ngaphezu kwezingxenye ezimbili endaweni ye-graphite electrode, futhi ukukhubazeka noma usayizi wezimbobo akufanele udlule idatha ekuthebula elingezansi elishiwo.

2.Akukho ukuqhekeka okuvundlile endaweni ye-electrode.Ngokuqhekeka kwe-longitudinal, ubude bayo akufanele bube ngaphezu kuka-5% wesiyingi se-electrode yegraphite, ububanzi bayo kufanele bube phakathi kwebanga elingu-0.3-1.0mm. Idatha yokuqhekeka kweLongitudinal ngaphansi kuka-0.3mm idatha kufanele bangabi nandaba

3. Ububanzi bendawo emagebhugebhu (emnyama) endaweni ye-electrode yegraphite akumele bube ngaphansi kwe-1/10 yesiyingi se-electrode ye-graphite, nobude bendawo emagebhugebhu (emnyama) ibe ngaphezu kwe-1/3 yobude be-electrode yegraphite. akuvunyelwe.