I-Small Diameter Furnace Graphite Electrode yesithando somlilo se-arc kagesi semboni yensimbi kanye ne-Foundry

Ipharamitha Yezobuchwepheshe

Ishadi 1:Ipharamitha Yobuchwepheshe Ye-Electrode Encane Ye-Diameter Graphite

| Ububanzi | Ingxenye | Ukumelana | Amandla e-Flexural | I-Modulus Encane | Ukuminyana | I-CTE | Umlotha | |

| Intshi | mm | μΩ·m | I-MPa | I-GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Ishadi 2:Ikhono Lamanje Lokuthwala Le-Electrode Encane Eyi-Diameter Graphite

| Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Ishadi 3: Usayizi We-Graphite Electrode & Ukubekezelela I-Diameter Encane I-Graphite Electrode

| Ububanzi Okuzisholo | Ububanzi Bangempela(mm) | Ubude Begama | Ukubekezelelana | |||

| Intshi | mm | Ubukhulu. | Okuncane. | mm | Intshi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Isicelo Esiyinhloko

- Ukuncibilika kwe-calcium carbide

- Ukukhiqizwa kwe-Carborundum

- Ukucwenga i-Corundum

- Ukuncibilika kwezinsimbi ezingavamile

- I-Ferrosilicon plant refractory

Ukunikezwa Kwemiyalo Nokusetshenziselwa Ama-Electrode E-graphite

1.Susa isembozo sokuzivikela somgodi omusha we-electrode, hlola ukuthi intambo emgodini we-electrode iphelele futhi intambo ayiphelele, thintana nonjiniyela ochwepheshe ukuze unqume ukuthi i-electrode ingasetshenziswa yini;

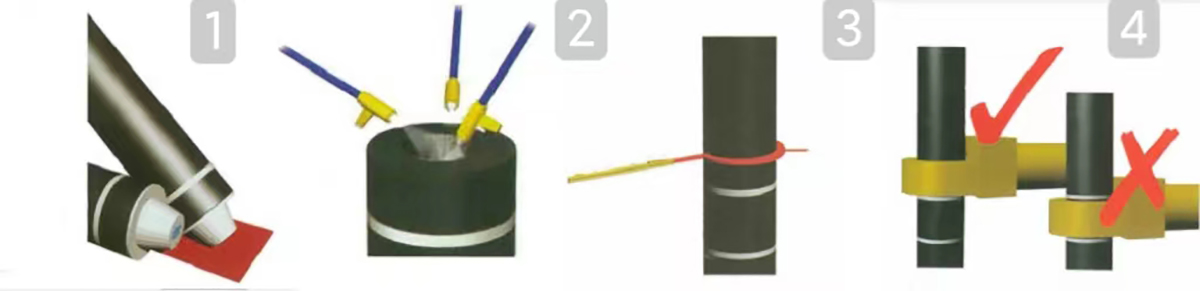

2.Khipha isiphanyeko se-electrode embotsheni ye-electrode ekugcineni, bese ubeka umcamelo othambile ngaphansi kwesinye isiphetho se-electrode ukuze ugweme ukulimaza ilunga le-electrode;(bona pic1)

3.Sebenzisa umoya ocindezelwe ukuze ushaye uthuli nama-sundries endaweni kanye nembobo ye-electrode exhumayo, bese uhlanza indawo engaphezulu nesixhumi se-electrode entsha, uyihlanze ngebhulashi;(bona pic2)

4.Phakamisa i-electrode entsha ngaphezu kwe-electrode elindile ukuze ihambisane nembobo ye-electrode futhi iwe kancane;

5.Sebenzisa inani elifanele letorque ukuze ukhiye kahle i-electrode;(bona pic3)

6.Umbambi we-clamp kufanele ukhishwe kulayini we-alamu.(bona pic4)

7.Ngenkathi yokucwenga, kulula ukwenza i-electrode ibe mncane futhi ibangele ukuphuka, ukuwa okuhlangene, ukwandisa ukusetshenziswa kwe-electrode, sicela ungasebenzisi ama-electrode ukuphakamisa okuqukethwe kwekhabhoni.

8.Ngenxa yezinto zokusetshenziswa ezihlukene ezisetshenziswa umkhiqizi ngamunye kanye nenqubo yokukhiqiza, izakhiwo ezingokoqobo namakhemikhali zama-electrode namalunga omkhiqizi ngamunye. Ngakho-ke ekusetshenzisweni, ngaphansi kwezimo ezijwayelekile, Sicela ungahlanganisi ukusebenzisa ama-electrode namajoyinti akhiqizwa abakhiqizi abahlukene.