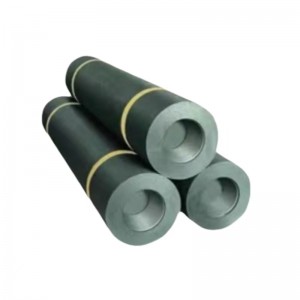

I-Frnace Graphite Electrode Amandla Avamile RP Ibanga 550mm Ububanzi Obukhulu

Ipharamitha Yezobuchwepheshe

| Ipharamitha | Ingxenye | Iyunithi | RP 550mm(22”) Idatha |

| Ububanzi Okuzisholo | I-Electrode | mm(intshi) | 550 |

| I-Max Diameter | mm | 562 | |

| Ububanzi obuncane | mm | 556 | |

| Ubude Begama | mm | 1800/2400 | |

| Ubude obukhulu | mm | 1900/2500 | |

| Ubude obuncane | mm | 1700/2300 | |

| Ukuminyana Kwamanje Okuphezulu | KA/cm2 | 12-15 | |

| Ikhono Lamanje Lokuthwala | A | 28000-36000 | |

| Ukumelana Okuqondile | I-Electrode | μΩm | 7.5-8.5 |

| Ingono | 5.8-6.5 | ||

| Amandla e-Flexural | I-Electrode | Mpa | ≥8.5 |

| Ingono | ≥16.0 | ||

| I-Modulus Encane | I-Electrode | I-Gpa | ≤9.3 |

| Ingono | ≤13.0 | ||

| Ukuminyana kwenqwaba | I-Electrode | g/cm3 | 1.55-1.64 |

| Ingono | |||

| I-CTE | I-Electrode | ×10-6/℃ | ≤2.4 |

| Ingono | ≤2.0 | ||

| Okuqukethwe Umlotha | I-Electrode | % | ≤0.3 |

| Ingono | ≤0.3 |

QAPHELA: Noma yiziphi izimfuneko ezithile kubukhulu zinganikezwa.

I-Graphite Electrode Factors In Steelmaking

Embonini yokwenza insimbi, inqubo ye-Electric Arc Furnace (EAF) ingenye yezindlela ezisetshenziswa kakhulu. Ukukhetha i-electrode efanele ye-graphite kubalulekile kule nqubo. Ama-electrode e-graphite e-RP (Amandla Avamile) ayintandokazi ngenxa yokufinyeleleka kwawo kanye nokufaneleka kokusebenza kwesithando somlilo esiphakathi kwamandla.

Lapho ukhetha i-RP graphite electrode, kunezici ezimbalwa ezibalulekile okufanele uzicabangele. Enye i-diameter ye-electrode, okufanele ifanele usayizi othile wesithando somlilo kanye nezidingo zokukhiqiza. Ibanga le-electrode lingenye into; Ama-electrode e-RP graphite ngokuvamile ahlukaniswa abe amamaki amane ngokuya ngokumelana kwawo kagesi namandla aguqukayo. Ibanga elifanele kufanele likhethwe ngokusekelwe ezidingweni ezithile zokusebenza kwesithando somlilo.

Idatha Enconyiwe Yokufanisa I-Graphite Electrode Nesithando Somlilo Se-Electric Arc

| Amandla wesithando somlilo (t) | Ububanzi Bangaphakathi (m) | I-Transformer Capacity (MVA) | I-Graphite Electrode Diameter (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 | 12 | 10 | 6 | 350 |

| 20 | 3.95 | 15 | 12 | 7.5 | 350/400 |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 | 150 | --- | --- | |

I-Surface Quality Ruler

1.Ukukhubazeka noma izimbobo akufanele zibe ngaphezu kwezingxenye ezimbili endaweni ye-graphite electrode, futhi ukukhubazeka noma usayizi wezimbobo akufanele udlule idatha ekuthebula elingezansi elishiwo.

2.Akukho ukuqhekeka okuvundlile endaweni ye-electrode.Ngokuqhekeka kwe-longitudinal, ubude bayo akufanele bube ngaphezu kuka-5% wesiyingi se-electrode yegraphite, ububanzi bayo kufanele bube phakathi kwebanga elingu-0.3-1.0mm. Idatha yokuqhekeka kweLongitudinal ngaphansi kuka-0.3mm idatha kufanele bangabi nandaba

3. Ububanzi bendawo emagebhugebhu (emnyama) endaweni ye-electrode yegraphite akumele bube ngaphansi kwe-1/10 yesiyingi se-electrode ye-graphite, nobude bendawo emagebhugebhu (emnyama) ibe ngaphezu kwe-1/3 yobude be-electrode yegraphite. akuvunyelwe.

Idatha Yokukhubazeka Okungaphezulu Kweshadi Le-Graphite Electrode

| Ububanzi Okuzisholo | Idatha Yesiphambeko(mm) | ||

| mm | intshi | Ububanzi(mm) | Ukujula(mm) |

| 300-400 | 12-16 | 20–40 | 5–10 |

| 450-700 | 18-24 | 30–50 | 10–15 |