I-HP24 Graphite Carbon Electrodes Dia 600mm Electrical Arc Furnace

Ipharamitha Yezobuchwepheshe

| Ipharamitha | Ingxenye | Iyunithi | HP 600mm(24”) Idatha |

| Ububanzi Okuzisholo | I-Electrode | mm(intshi) | 600 |

| I-Max Diameter | mm | 613 | |

| Ububanzi obuncane | mm | 607 | |

| Ubude Begama | mm | 2200/2700 | |

| Ubude obukhulu | mm | 2300/2800 | |

| Ubude obuncane | mm | 2100/2600 | |

| Ukuminyana Kwamanje | KA/cm2 | 13-21 | |

| Ikhono Lamanje Lokuthwala | A | 38000-58000 | |

| Ukumelana Okuqondile | I-Electrode | μΩm | 5.2-6.5 |

| Ingono | 3.2-4.3 | ||

| Amandla e-Flexural | I-Electrode | Mpa | ≥10.0 |

| Ingono | ≥22.0 | ||

| I-Modulus Encane | I-Electrode | I-Gpa | ≤12.0 |

| Ingono | ≤15.0 | ||

| Ukuminyana kwenqwaba | I-Electrode | g/cm3 | 1.68-1.72 |

| Ingono | 1.78-1.84 | ||

| I-CTE | I-Electrode | ×10-6/℃ | ≤2.0 |

| Ingono | ≤1.8 | ||

| Okuqukethwe Umlotha | I-Electrode | % | ≤0.2 |

| Ingono | ≤0.2 |

QAPHELA: Noma yiziphi izimfuneko ezithile kubukhulu zinganikezwa.

Indlela yokufanisa i-Graphite Electrode ne-Electric Arc Furnace

Ama-electrode e-graphite ayizingxenye ezibalulekile zenqubo yokwenza insimbi ye-Electric Arc Furnace (EAF). Kodwa-ke, izindleko zenqubo yokwenza insimbi zithintwa yi-electrode oxidation, sublimation, dissolution, spalling, and breaking. Izindaba ezinhle ukuthi ukukhethwa kwe-graphite electrode, ukusetshenziswa, nokugcinwa kunganciphisa ngempumelelo ukusetshenziswa kwe-electrode. Kulesi sihloko, sizoxoxa ngendlela yokukhetha i-electrode efanele ye-graphite nokuthi ungayigcina kanjani kahle ukuze uthole okuningi ekutshaleni kwakho.

Imininingwane

Ukufanisa phakathi komthamo wesithando somlilo kagesi, umthwalo wamandla we-transformer nosayizi we-electrode.

| Isithando somlilo | Ububanzi Bangaphakathi (m) | I-Transformer Capacity (MVA) | I-Graphite Electrode Diameter (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 | 12 | 10 | 6 | 350 |

| 20 | 3.95 | 15 | 12 | 7.5 | 350/400 |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 | 150 | --- | --- | |

Umyalelo Wokunikeza Nokusetshenziswa

- 1.Susa isembozo sokuzivikela somgodi omusha we-electrode, hlola ukuthi intambo emgodini we-electrode iphelele futhi intambo ayiphelele, thintana nonjiniyela ochwepheshe ukuze unqume ukuthi i-electrode ingasetshenziswa yini;

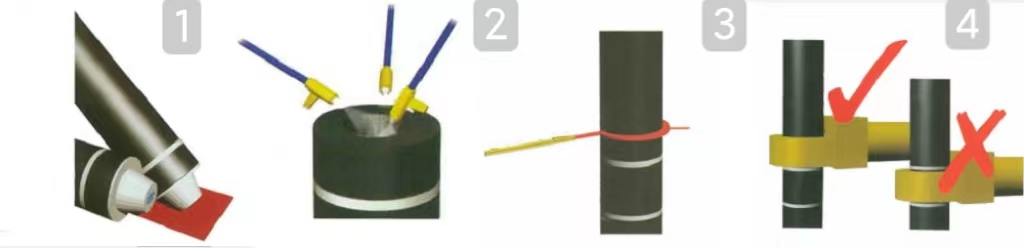

- 2.Khipha isiphanyeko se-electrode emgodini we-electrode ekugcineni, bese ubeka i-cushion ethambile ngaphansi komunye umkhawulo we-electrode ukuze ugweme ukulimaza i-electrode joint; (bona isithombe1)

- 3.Sebenzisa umoya ocindezelwe ukuze ushaye uthuli nama-sundries ebusweni kanye nembobo ye-electrode yokuxhuma, bese uhlanza indawo kanye nesixhumi se-electrode entsha, uyihlanze ngebhulashi; (bona isithombe2)

- 4.Phakamisa i-electrode entsha ngaphezu kwe-electrode elindile ukuze ihambisane nembobo ye-electrode futhi iwe kancane;

- 5.Sebenzisa inani elifanele letorque ukuze ukhiye kahle i-electrode; (bheka isithombe3)

- 6.Umbambi we-clamp kufanele ukhishwe kulayini we-alamu. (bheka isithombe4)

- 7.Ngenkathi yokucwenga, kulula ukwenza i-electrode ibe mncane futhi ibangele ukuphuka, ukuwa okuhlangene, ukwandisa ukusetshenziswa kwe-electrode, sicela ungasebenzisi ama-electrode ukuphakamisa okuqukethwe kwekhabhoni.

- 8.Ngenxa yezinto zokusetshenziswa ezihlukene ezisetshenziswa umkhiqizi ngamunye kanye nenqubo yokukhiqiza, izakhiwo ezingokoqobo namakhemikhali zama-electrode namalunga omkhiqizi ngamunye. Ngakho-ke ekusetshenzisweni, ngaphansi kwezimo ezijwayelekile, Sicela ungahlanganisi ukusebenzisa ama-electrode namajoyinti akhiqizwa abakhiqizi abahlukene.