I-High Density Small Diameter Furnace Graphite Electrode Yesithando somlilo seLadle Esiqhumayo Esincibilikisa Insimbi

Ipharamitha Yezobuchwepheshe

Ishadi 1:Ipharamitha Yobuchwepheshe Ye-Electrode Encane Ye-Diameter Graphite

| Ububanzi | Ingxenye | Ukumelana | Amandla e-Flexural | I-Modulus Encane | Ukuminyana | I-CTE | Umlotha | |

| Intshi | mm | μΩ·m | I-MPa | I-GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Ishadi 2:Ikhono Lamanje Lokuthwala Le-Electrode Encane Eyi-Diameter Graphite

| Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Ishadi 3: Usayizi We-Graphite Electrode & Ukubekezelela I-Diameter Encane I-Graphite Electrode

| Ububanzi Okuzisholo | Ububanzi Bangempela(mm) | Ubude Begama | Ukubekezelelana | |||

| Intshi | mm | Ubukhulu. | Okuncane. | mm | Intshi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Isicelo Esiyinhloko

- Ukuncibilika kwe-calcium carbide

- Ukukhiqizwa kwe-Carborundum

- Ukucwenga i-Corundum

- Ukuncibilika kwezinsimbi ezingavamile

- I-Ferrosilicon plant refractory

Ukunikezwa Kwemiyalo Nokusetshenziselwa Ama-Electrode E-graphite

1.Sebenzisa amathuluzi okuphakamisa akhethekile ukuze uphile i-electrode yegraphite gwema ukonakala ngesikhathi sokuthutha.(bona isithombe1)

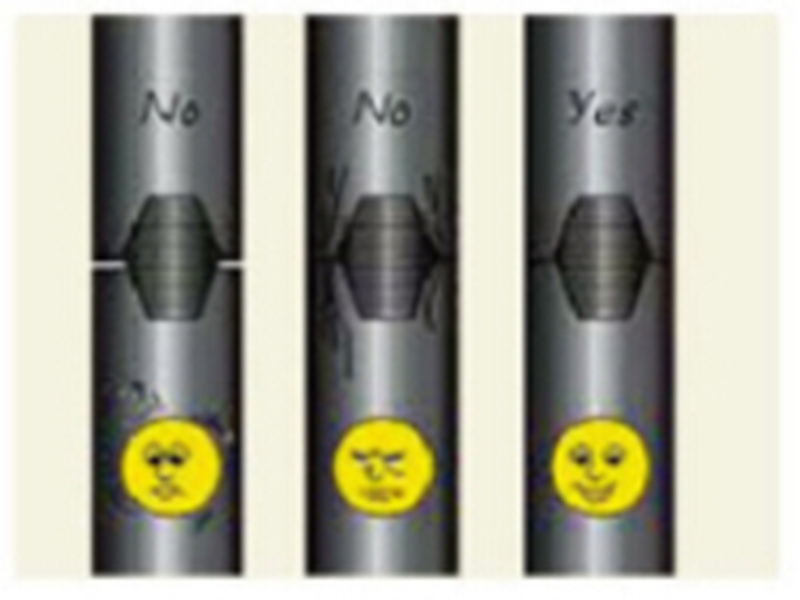

2.I-electrode ye-graphite kufanele igwenywe ukuba ingamanziswa noma imanziswe yimvula, iqhwa, igcinwe yomile.(bona pic2)

3.Ukuhlola ngokucophelela ngaphambi kokusetshenziswa qinisekisa ukuthi isokhethi nentambo yengono ikulungele ukusetshenziswa, okuhlanganisa nokuhlolwa kwephitshi, ipulaki.(bona pic3)

4.Hlanza ingono nezintambo zesokhethi ngomoya ocindezelweyo.(bona pic4)

5.Ngaphambi kokusetshenziswa, i-electrode yegraphite kumele yomiswe esithandweni, izinga lokushisa lokumisa kufanele libe ngaphansi kuka-150 ℃, isikhathi esomile kufanele sibe ngaphezu kwamahora angu-30. (bona pic5)

6.I-electrode yegraphite kufanele ixhunywe ngokuqinile futhi iqonde ngetorque yokuqinisa efanelekile.(bona pic6)

7.Ukuze ugweme ukuphuka kwe-graphite electrode, beka ingxenye enkulu endaweni ephansi kanye nengxenye encane endaweni ephezulu.