Ukusetshenziswa Kwe-Graphite Electrode Kwe-Corundum Refining Electric Arc Furnace Small Diameter Furnace Electrodes

Ipharamitha Yezobuchwepheshe

Ishadi 1:Ipharamitha Yobuchwepheshe Ye-Electrode Encane Ye-Diameter Graphite

| Ububanzi | Ingxenye | Ukumelana | Amandla e-Flexural | I-Modulus Encane | Ukuminyana | I-CTE | Umlotha | |

| Intshi | mm | μΩ·m | I-MPa | I-GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | I-Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | I-Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ingono | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Ishadi 2:Ikhono Lamanje Lokuthwala Le-Electrode Encane Eyi-Diameter Graphite

| Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | Ububanzi | Umthwalo Wamanje | Ukuminyana Kwamanje | ||

| Intshi | mm | A | A/m2 | Intshi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Ishadi 3: Usayizi We-Graphite Electrode & Ukubekezelela I-Diameter Encane I-Graphite Electrode

| Ububanzi Okuzisholo | Ububanzi Bangempela(mm) | Ubude Begama | Ukubekezelelana | |||

| Intshi | mm | Ubukhulu. | Okuncane. | mm | Intshi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Isicelo Esiyinhloko

- Ukuncibilika kwe-calcium carbide

- Ukukhiqizwa kwe-Carborundum

- Ukucwenga i-Corundum

- Ukuncibilika kwezinsimbi ezingavamile

- I-Ferrosilicon plant refractory

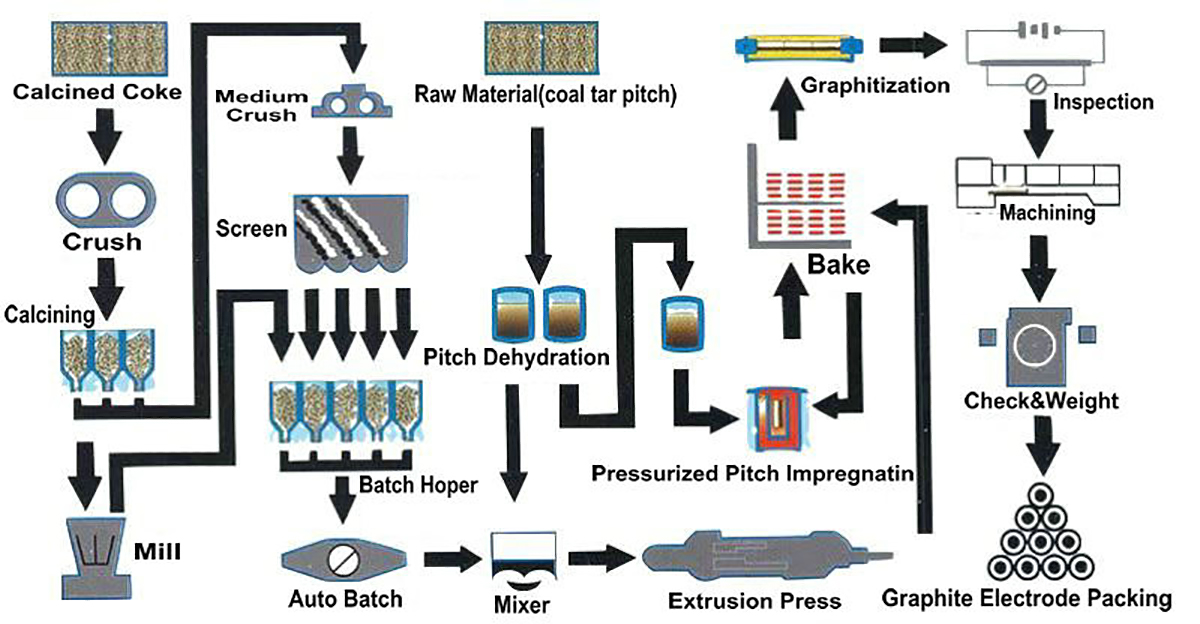

I-RP Graphite Electrode Production Process

Izinzuzo ze-Gufan

1. Yenziwe ngezinto ezisezingeni eliphezulu ze-graphite, ama-electrode ethu amancane we-graphite akhiwe ukuze amelane namazinga okushisa aphakeme futhi anikeze ukuqhutshwa kogesi okuhle kakhulu. Lokhu kuqinisekisa inqubo yokuncibilikisa ezinzile futhi ephumelelayo, okuholela kukhwalithi yomkhiqizo ephakeme kanye nokunciphisa ukusetshenziswa kwamandla.

2. Usayizi omncane walawa ma-electrode uvumela ukulawula okunembe kakhudlwana phezu kwenqubo yokuncibilikisa, okuwenza aphelele ezinhlelweni ezidinga ukunemba okuphezulu nemiphumela ecushwe kahle. Kungakhathaliseki ukuthi ukhiqiza ama-alloys noma izinsimbi zokucwenga, ama-electrode ethu azokusiza ufinyelele umphumela oyifunayo ngokunemba okungenakuqhathaniswa.

3. Ama-electrode ethu amancane e-graphite afanele izimboni eziningi, okuhlanganisa ukukhiqiza insimbi, ukucubungula amakhemikhali, kanye nokusakazwa kwensimbi. Kungakhathaliseki ukuthi ungakanani umsebenzi wakho, ama-electrode ethu angenziwa ngokwezifiso ukuze ahlangabezane nezidingo zakho ezithile.

4. Ekwenziweni kwensimbi, ama-electrode ethu amancane angama-graphite asetshenziswa kuma-arc kagesi, lapho edlala indima ebalulekile ekukhiqizeni insimbi yezinga eliphezulu. Ubukhulu bawo obuncane buvumela ukulawula okunembile phezu kwenqubo yokuncibilika, ukuqinisekisa imiphumela engaguquki futhi kuncishiswe imfucuza.

5. Ekucutshungulweni kwamakhemikhali, ama-electrode ethu abalulekile ekukhiqizeni i-calcium carbide kanye nokucwengwa kwe-carborundum. Lezi zinqubo zidinga ukulawula izinga lokushisa okunembile, okulethwa ama-electrode ethu ngokunemba okukhulu.

6. Ukuze kukhishwe insimbi, ama-electrode ethu amancane e-graphite asetshenziswa ekuncibilikiseni izinsimbi ezingavamile kanye nezitshalo ze-Ferrosilicon. I-conductivity ephakeme ye-graphite ivumela ukuncibilika okuphumelelayo kwezinsimbi, okuholela emijikelezweni yokukhiqiza esheshayo kanye nokukhiqiza okuphezulu jikelele.